Boost your productivity

Repair your controllers

Improve your automation

We provide targeted repair and controller replacement services, improving your machine tools and helping you avoid costly refits, along with tailored automation solutions for new and existing machinery.

Is your production at a standstill? We’ll find a solution!

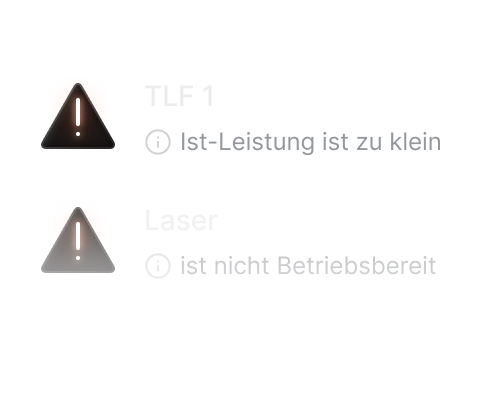

Machinery stoppages & unexpected downtimes

The unexpected failure of your Trumpf machine tools can be costly. Our preventive maintenance experts can uncover faults and minimise this risk. If your production is already at a standstill, we can provide the fast and professional troubleshooting you need to get back up and running.

Slow processes & wasted potential

Your machines could run up to 30% faster yet unoptimised controllers, incorrect parametrisations and inefficient processes are slowing your production down.

Is your automation or warehousing system not working properly?

Is your production still too manual because you think automation is too expensive or too complicated? We connect old automation solutions with new systems, or introduce automations and train you how to use them. Automating your night shifts, for example, can significantly reduce staffing costs.

Are your staff struggling with machine controls?

Insufficient training and outdated software can lead to poor cutting results, more reworking and frustrated staff. This not only reduces your productivity, but can also cause you to lose valuable workers to the competition.

Outdated software & incorrect programming

Operating errors, collisions and costly repairs are often the result of poor software optimisation. Many companies decide against updates or use incorrect settings, costing them both time and money.

Increasing costs of maintenance & spare parts

Many companies waste money on expensive repairs or new machinery when a more cost-effective repair or alternative spare parts would be the better option.

All-round machinery service

More than just service – efficiency, expertise & speed

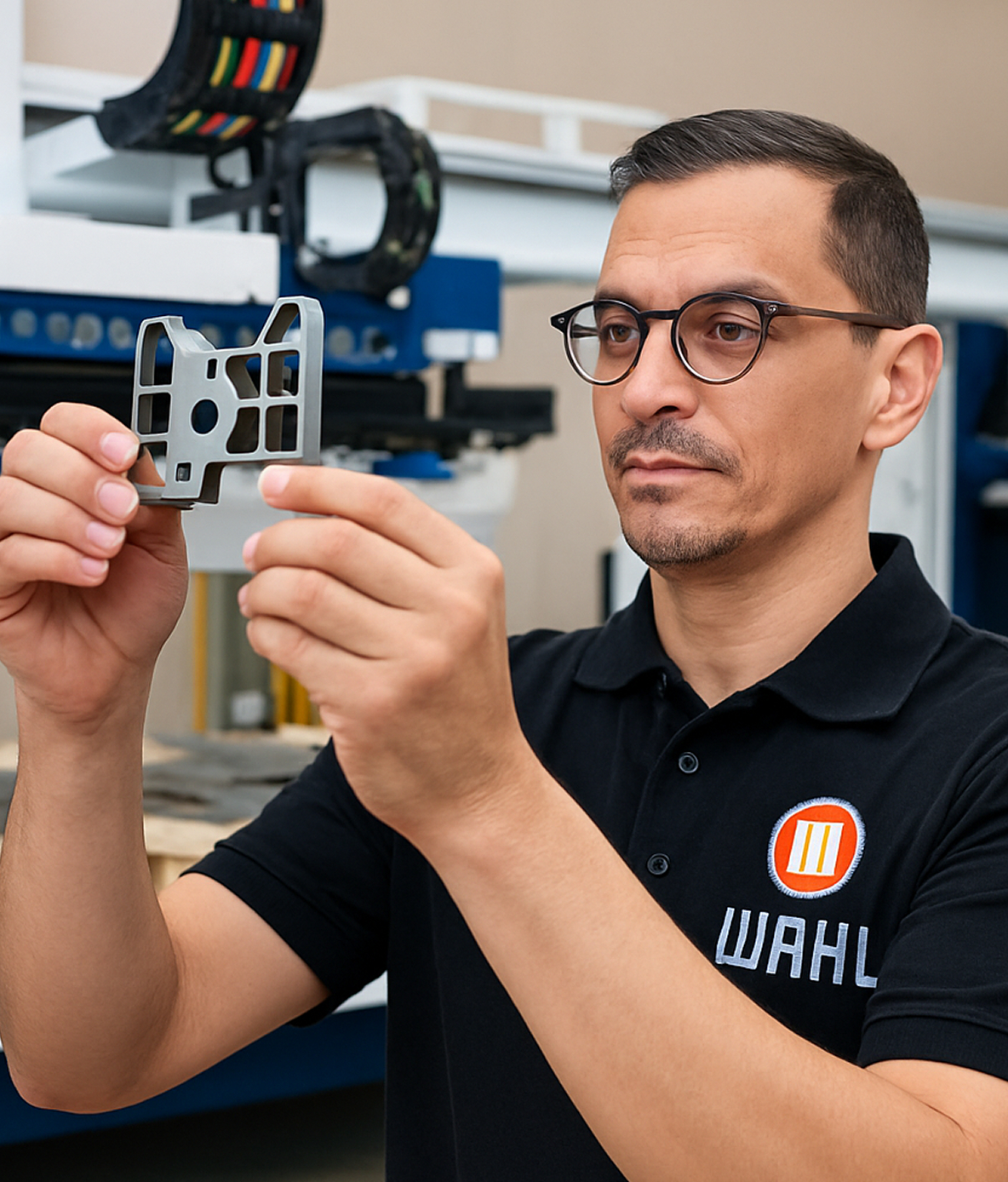

Problems with machinery are often just the tip of the iceberg. Our expert technicians provide much more than just the standard service. They not only understand the hardware, but are also able to optimise your software, processes and even your team. This not only helps to quickly overcome downtimes, but also prevents them from happening over the long term.

Machinery, controls & software

Our team knows all Trumpf sheet metal processing systems inside out and can quickly find the best solution.

Get back up and running fast

We fast-track emergencies so that you can restart production as quickly as possible.

Fewer problems, greater efficiency

We provide advice, train your team and improve processes to prevent faults from occurring in the first place.

Die klare Analyse und schnelle Umsetzung haben unsere Prozesse enorm verbessert. Ein echter Gewinn für unsere Produktion und das Team.

Sabine K.

Bonn

Professional services that keep you going.

Our services

With a combination of technical expertise and many years of experience, the team at Wahl makes sure that your machines run smoothly, your processes are more efficient and your team works together perfectly.

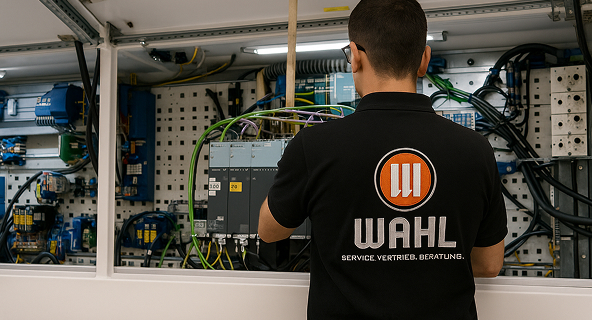

Machinery service & emergency help

Has your production come to a halt? Don’t worry! We can provide fast diagnosis and repair, either on site or remotely, so you can get back up and running quickly.

Process optimisation & automation

We adapt your machinery, software and processes to help you reduce costs and shorten production times.

Spare parts & repairs

Can’t get hold of the parts you need? Does your machine need an expensive refit? We can procure the right parts, repair your machines or find a suitable alternative solution.

Strategic consulting & training

From advice on machinery investments to staff training, we make sure that your technology and your team work hand-in-hand.

Maximum efficiency, minimal downtimes

How to make your production run more effectively and profitably

Unnecessary delays and inefficient processes are costing you time and money every day. By optimising processes, training staff and making clever use of automation, you can reduce stoppages and boost your productivity without the need for major investments.

Faster processes & more output

Outdated processes and incorrect machinery settings are holding your production back. Targeted optimisation enables you to reduce throughput times by up to 30% and boost your output.

Fewer stoppages, less stress

Machinery stoppages cost time and money. A combination of precautionary checks, regular backups and clever emergency strategies enables you to prevent unexpected downtimes and make your production more reliable.

Reduced costs, greater efficiency

Many companies waste money on expensive repairs or new machinery when a more cost-effective repair or alternative spare parts would be the better option.

Better staff retention & less fluctuation

Insufficient training and outdated software can lead to poor cutting results, more reworking and frustrated staff. This not only reduces your productivity, but can also cause you to lose valuable workers to the competition.

More automation, fewer staffing issues

Struggling to find qualified staff? The right automation can help your team work more effectively and reduce the need for additional personnel.

All-round machinery service

Get the most from your machinery, processes and staff

From downtimes and inefficient processes to increasingly demanding requirements, many sheet metal processing companies face the same challenges. As a qualified service and application technician and consultant, as well as from my own experience in production, I know where the problems often lie. I spent years in production halls, working on machinery and improving processes. During this time, I not only repaired systems, but also developed sophisticated manufacturing processes. I understand the technology, the controls and the processes, and I have seen the problems that arise from these myself. If my experience with machine tools has taught me anything, it’s that just repairing a defective machine is not enough. Companies that want reliable production over the long term need a smart approach. They need the right settings for their machines, lean processes and well-trained staff. We’d love to help you with this!

Fast, effective, smart.

4 steps to more effective production

From the moment you pick up the phone to results that last, this is how we work together.

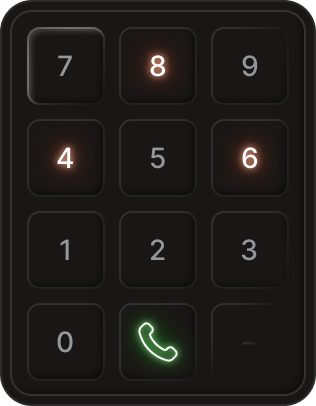

1. Query & initial assessment

Get in touch via phone or e-mail. We can often analyse problems on the phone and quickly provide an initial assessment.

2. Fault diagnosis & planning

If remote diagnosis is not enough, we can take a closer look on site. We identify the problems and agree a strategy to solve them.

3. Implementation & solution

We get to work solving the problem, whether by repairing your machinery, replacing components or adjusting the controls. If necessary, we can also give you instructions so that you can do it yourself.

4. Optimisation & prevention

After dealing with the fault, we ensure a lasting improvement. We optimise processes, check your automation systems and prevent future stoppages.

How much more could your machines achieve?

Unnecessary production stoppages, high energy costs and inefficient processes are all avoidable. With the right improvements, you can get the most from your machinery and reduce your operating costs faster than you expect.

50%

of companies have a significant need for optimisation

+30%

faster processes thanks to optimised machine controls

30%

lower energy costs through more precise cutting processes

“I’ve repaired machines, planned improvements and developed optimised processes myself. Now I help others do the same.”

Konstantin Wahl

Managing Director

Wahl SVB GmbH

Trouble-free production starts here!

Fewer stoppages – fast troubleshooting

Boost productivity – less reworking, more output

Technical excellence – machinery & software in perfect harmony

Frequently asked questions

Here you can find the answers to the most important questions about our services, how we work and how you can benefit.

Fixing machinery stoppages is our no. 1 priority. If necessary, we can reorganise other servicing appointments to get your production back up and running as quickly as possible. It is often possible to narrow down a problem on the phone, making the on-site repair easier and faster.

Yes, our technicians have expert knowledge of all kinds of Trumpf machinery (e.g. flat-bed systems, stamping machines, combined machines, press brakes, automations and software), and can provide you with all the help you need.

That is hard to say, as every project is different. Please contact us for a free and non-binding consultation. This will allow us to give an initial assessment of how long the optimisation project will take.

Sure. We can track down scarce spare parts, procure components that do the same job or repair your existing parts for the job at hand. We can also replace controllers to help you avoid costly refits.

Backups are incredibly important. Without a backup, a defect in your machine’s hard drive can wipe out machine-specific data and shut down your production for a long time. We would be happy to perform professional backups for you.

We offer training sessions for machinery and programming that are suitable for both beginners and advanced users. We can also help train your staff in how to perform the necessary servicing and maintenance work. Simply get in touch and tell us what you need.

Machines never break down during training sessions, only in real-life production scenarios. We can support and optimise your production without interrupting operations. In doing so, we go one step further than standard service companies by taking an all-round look at your production, rather than concentrating on individual machines.

Working with your machinery gives us an idea of which other machines would be a good addition. We would be happy to help you procure the right machine for the right price and get it back in good working order if necessary.

We will be happy to help you find buyers for your used Trumpf machines. Simply get in touch!